cement making plant ball mill operation clinker

2020-09-09T05:09:28+00:00

Use Cement Ball Mill Grinding Cement Clinker

Cement ball mill is widely used in cement production, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral 10/12/2019 Cement drytype ball mill is mainly used for grinding raw materials and clinker (finished products and raw materials) in cement plant, and also for grinding various ores and other grindable materials in metallurgy, chemical Cement Ball Mill JXSC MachineThe cement ball mill is a kind of cement grinding mill It is mainly used for grinding theclinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical and electric power enterprises It has the characteristics of strong adaptability to materials, continuous production, large crushing ratio and easy to adjust the fineness of cement ball mill for clinker grinding plant Machinery

Clinker Production Clinker Plant Cement Plant Equipment

As the temperature of the material increases, the mineral becomes a liquid phase and reacts to form a large amount (clinker) After the clinker is fired, the temperature begins to decrease As a leading cement plant manufacturer, AGICO Cement supplies cement equipment for clinker plant, such as cement rotary kiln, preheater in cement plant Many cement plants use bituminous coal as the fuel of rotary kiln, so the ash content, volatile matter, calorific value, fineness, and moisture of coal fines will affect the clinker calcination process in the kiln Coal fines Coal fines are usually prepared by Cement Clinker Quality Control AGICO Cement Plant02/12/2019 Clinker cooler: the clinker cooler is heat exchange equipment, clinker cooler use air as medium, pass through the hightemperature clinker and cool the cement clinker, at the same time, recovery the waste heat, promote the thermal efficiencyOur cement cooler has advantages of high thermal efficiency, high clinker quality, fast cooling, high operation rateClinker Plant Cement Plant Cement Equipment For

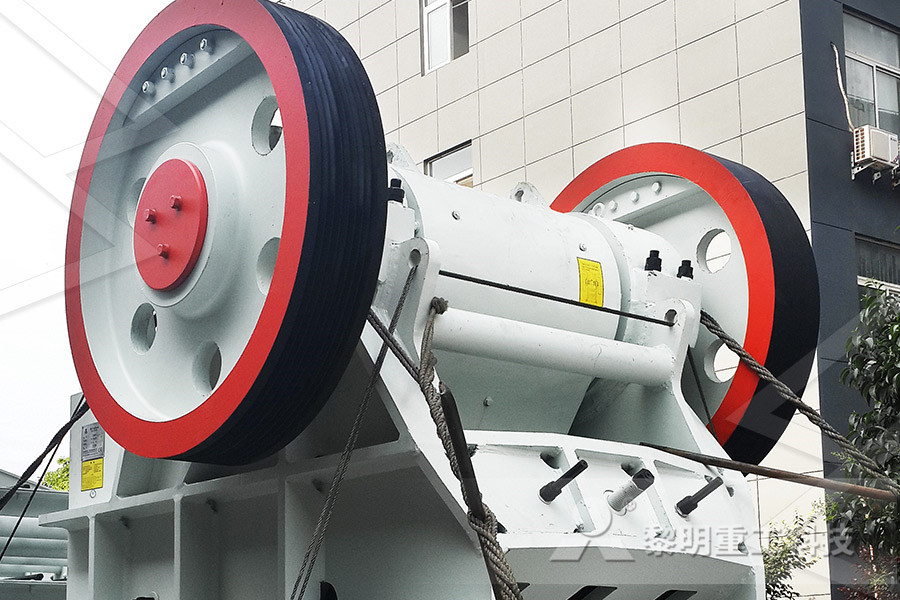

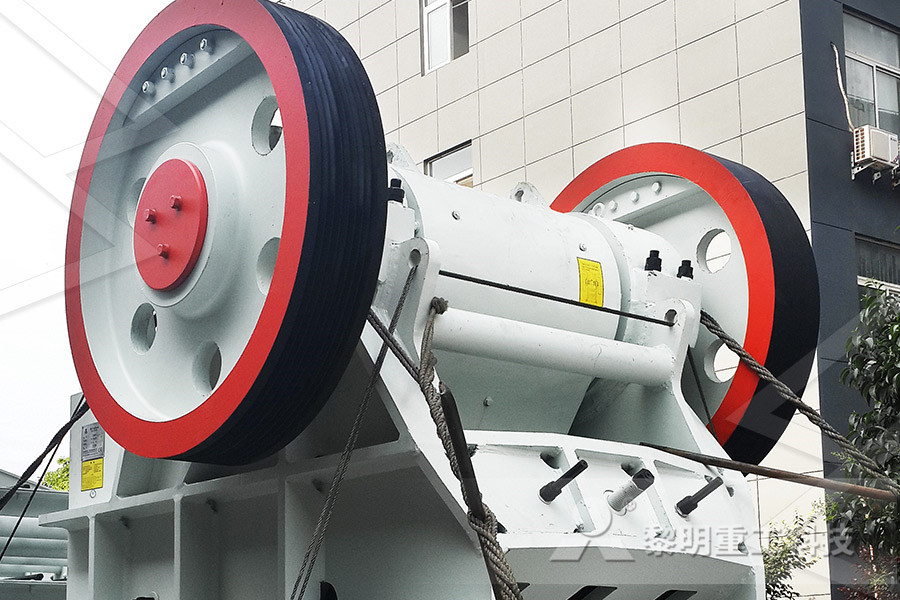

Clinker Cement Plant Manufacturers, Clinker Plant Machines

Clinker is the raw material used to manufacturing the cement The clinker plant comprises of feed pre crusher, feed hopper, table feeders, ball mill, packaging cement plant and material handling equipment However, the operation of the plant consists of basically four processes viz quarry, raw mill grinding, coal grinding and kilnburningCement ball mill working principle The material is uniformly fed into the first bin of the cement ball mill by the feeding device through the hollow shaft The first bin has stepped lining or corrugated lining, which is filled with steel balls of different specificationsBall Mill For Sale Cement Mill AGICO Cement PlantAs a trusted cement plant manufacturer of China, AGICO Cement can provide highquality cement mill and other kinds of cement equipment at competitive prices Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etcCement Mill Cement Ball Mill Vertical Cement Mill AGICO

85tph Cement Ball Mill Put Into Operation in Indian

Home » Solutions » 85tph Cement Ball Mill Put Into Operation In Indian Cement Plant Production capacity: 85t/h Processed material: Cement clinker Input size: ≤25mm Equipment: 85t/h cement ball mill, dryer, separator, Ball Mill In Clinker Grinding Plant FOB Reference Price: Get Latest Price Ball mill for grinding cement unitOperation of ball mill in cement grinding unitminig machine cement ball mill overview the ball mill for clinker is an efficient tool for fine powder grinding it is mainly used to grind the clinker and raw materials in cement industry and also can be applied in Ball Mill In Clinker Grinding Plant philippelangebeComing now to the ball mill we are reaching the ex perimental stage of milling as applied to cement clinker Ball mills and pebble mills have been used in a number of plants hie mill in its Cement Clinker Grinding Plant China Henan Zhengzhou Main Equipment Vertical Roller Mill Cement Ball Mill Air Classifier Send email vip clinker grinding by ball mill sarlblissonfr

clinker grinding installclinker grinding intensive

25/01/2022 cement mill operation getting low blaine MWR Cement grinding The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness ball mill operation clinker cadhousecoza Jan 08, 2014 A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder cement mill operation CGM Grinding Plant Ball Mill Circuit Operation, Simulation, Optimisation, Ball Mill Operation and Control with Cement Mill,ball mill operation clinker ivaloresEnergy Saving Cement Ball Mill For Clinker Grinding Cement Plant Pdf Dyno Dynamics No 12004 New cement grinding plant for the New cement grinding plant for the Koromacno worksHOLCIM Hrvatska dooCroatia Location of the new grinding plant The new plant will be built in parallel to the existing old mill buildingIn this way the infrastructure the facilities for clinker ball mill for cement grinding plant

cement mill cement ball mill ball mill in cement plant

Cement Plant, Wholesale Various 300 to 7500 tpd ball mill in mini cement plant and cement clinker grinding plant for sale cement ball mill Page 1 of 2 International Cement Review re cement ball mill 23/07/2020 Grinding mill in cement plant Cement grinding plant of the year icr cement industry the mill uses around 105t of vega grinding balls to grind the clinker conscious of the plants location in an urban area to reduce the noise of the grinding process the mill building is covered in a special cladding to lower noise pollution by 32db to 82db when the mill is in Clinker Grinding Ball Mill In Cement PlantBall Mill Operation Clinker Clinker grinding mill operation online service cement mill wikipedia the free encyclopedia ball mills are normally operated at around 75 of critical speed cement mill wikipedia the free encyclopedia the hardness of clinker is important for the energy cost of the grinding process it depends both on the 60S Manual Response; 30Min Technical Ball Mill Operation Clinker angelvereinwerdaude

ball mill operation clinker penzionkamaradcz

Cement Making Plant Ball Mill Operation Clinker Ball mill operation clinker manual pricemining construction clinker cement turnkey grinding plant manufacturers a cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is Ball Mill For Sale, Ball Mill Price Cement Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates The cement mill Understanding CementWe also offers cement ball mill, cement plant machinery, cement plant components, vsk cement plant, ball mill for cement Read More (PDF) PROCESS AUTOMATION OF CEMENT PLANT The cement manufacturing process consists broadly of mining, crushing and grinding, blending, pyroprocessing, clinker cooling, clinker storage, finish milling, packing and cement milling plant

Cement Clinker Grinding Plant/Cement Mill/Cement

Ball Mill Working Principle Center drive and side drive are two common drive modes for a ball mill Center drive grinding mill means the motor shaft extends along the axis of mill body while side drive has a motor located on the side of the mill and torque is transmitted via the large girth gear which is bolted on the flange of the mill body Mini Clinker Grinding Unit / Ball Cement Clinker Grinding Ball Mill In Cement Plant FOB Reference Price: Get Latest Price Cement mill wikipediaA cement mill or finish mill in north american usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective Clinker Grinding Ball Mill In Cement Plantball mill operation clinker cadhousecoza Jan 08, 2014 A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder cement mill operation CGM Grinding Plant Ball Mill Circuit Operation, Simulation, Optimisation, Ball Mill Operation and Control with Cement Mill,ball mill operation clinker ivalores

Clinker Clinker Grinding Mill Operationball Mill

Clinker Grinding Mills Baghouse Inspection, Clinker feed to mill by pendulum clinker and cement everyting for clinker and cement in dec 11 2018 q kiln feed to clinker factor raw mill to kiln feed factor give me process a the raw meal to clinker factor is given by 11 loss on ignition at 1000c Clinker Clinker Grinding Mill OperationCement ball mill overview the ball mill for clinker is an efficient tool for fine powder grinding it is mainly used to grind the clinker The Cement Plant Operations Handbookrefractories – 9 Clinker cooling – 10 Kiln mechanical – 11 Emergency power – 12 Plant control systems 6 Cement milling process summary data – 8 Typical equipment downtime 110 1 Storage of ball mill operation clinker fermetureporteportail59frCement Plant, Wholesale Various 300 to 7500 tpd ball mill in mini cement plant and cement clinker grinding plant for sale cement ball mill Page 1 of 2 International Cement Review re cement ball mill cement mill cement ball mill ball mill in cement plant

Blaine Verses Feed In Cement Mill

Blaine Verses Feed In Cement Mill A cement mill or finish mill in North American usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills such as clinker feed rate in tonnes per hourball charging calculation in cement plant Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designsball charging calculation in cement plant