cement grinding optimisation sciencedirect

2019-11-09T16:11:00+00:00

Cement grinding optimisation ScienceDirect

01/11/2004 This paper describes the tools available for the analysis and optimisation of cement grinding circuits The application of the Bond based methodology as well as Population Balance Models (PBM) is presented using a case study The throughput of current conventional closed grinding circuit can be increased by 10–20% by precrushing the clinker using the The increasing demand for “finer cement” products, and the need for reduction in energy consumption and green house gas emissions, reinforces the need for grinding optimisationThis paper describes the tools available for the analysis and optimisation of cement grinding circuits The application of the Bond based methodology as well as Population Balance Models (PBM) Cement grinding optimisation ScienceDirect01/07/2018 Within the study, it was aimed to optimize both the energy utilization and the product quality of a conventional cement grinding circuit during CEM I 425R cement production In this context, an accurate sampling methodology was applied, which was supported by the computer simulations and the assessments of the quality properties of the finished product It Energy and cement quality optimization ScienceDirect

Energy and cement quality optimization ScienceDirect

This study aimed at optimizing both the energy efficiency and the quality of the end product by modifying the existing flowsheet of the cement grinding circuit As a general application, mill filter stream is sent to the air classifier owing to its coarser size distribution than the desired product However, the study proved that some further evaluations ie, quality tests and chemical Cement Grinding Optimisation Sciencedirect Optimization of cement and fly ash particle sizes to produce sustainable concretes Dale P Bentza⇑ Andrew S Hansenb John M Guynnb a Engineering Laboratory National Institute of Standards and Technology 100 Bureau Drive Stop 7313 Gaithersburg MD 208997313 USA bRoman Cement LLC Salt Lake City UT 84105 USA Cement Grinding Optimisation Sciencedirect Machine machinery01/11/2016 The study aimed at changing the current flow sheet of a cement grinding circuit with the aid of a simulation tool to improve the specific energy utilization of the circuit In this context, not only the size distribution but also the quality analysis was taken into account and used in simulation studies The study focussed on the static separator fine stream, which was Simulation aided flow sheet optimization of a cement

Optimization of Cement Manufacturing Process ScienceDirect

01/08/1987 :: J CEMENT GRINDING PROCESsll RlRNNJ PRCCESS ~eady stale arYl al:nnrnl stale cortrol of kiln ~lMilILroI J ~ Fig2 Control Systems for Cement Manufacturing Process G Nakamura, T Aizawa and K Nakase abnormal dy statestate programprogram 1 1 wk sintenng condition Fig 3 Kiln Computer Control Programs FROM PROCESS 1 Kiln ou cement grinding optimisation sciencedirect in mongolia Nov 01 2004 The increasing demand for “finer cement” products and the need for reduction in energy consumption and green house gas emissions reinforces the need for grinding optimisation This paper describes the tools available for the analysis and optimisation of cement grinding circuitsAs a leading cement grinding optimisation sciencedirect in mongoliaPortland Cement; Shale; Silica Fume; View all Topics Download as PDF Set alert About this page Drystack and compressed stabilised earthblock construction HC Uzoegbo, in Nonconventional and Vernacular Construction Materials, 2016 814 Limitations of CSEB constructionSome of the limitations in the application of soilcement products in construction Cement Product an overview ScienceDirect Topics

Nitrite binding in cement ScienceDirect

01/07/2001 Pore solution has been pressed out of hardened cement pastes prepared with the addition of nitritecontaining corrosion inhibitors The binding of nitcement grinding optimisation sciencedirect in mongolia Nov 01 2004 The increasing demand for “finer cement” products and the need for reduction in energy consumption and green house gas emissions reinforces the need for grinding optimisation This paper describes the tools available for the analysis and optimisation of cement grinding circuitsAs a leading cement grinding optimisation sciencedirect in mongoliaCement grinding optimisation ScienceDirect Nov 01 2004 The increasing demand for “finer cement” products and the need for reduction in energy consumption and green house gas emissions reinforces the need for grinding optimisation This paper describes the tools available for the analysis and optimisation of cement grinding circuits An estimation of the effect of cement grinding optimisation sciencedirect in china

cement grinding optimisation sciencedirect

Cement grinding optimisation ScienceDirect The setting up of greenfield cement projects means starting from scratch at a A few technological options now available for capacity enhancement through brownfield projects are as follows Grinding Pre grinding for raw mills View more ABB Ability Expert Optimizer for cement Advanced ABB Ability Expert Optimizer Cement grinding optimisation ScienceDirect Nov 01, 2004 The "work horse" of the cement grinding plant is the twocompartment ball mill, commonly called the tube mill Significant advances in model development were achieved in recent years ( Benzer et al, 2001, Benzer et al, 2003 ) through research on industrial scalecement grinding mill research uf1fr19/11/2016 Cement grinding optimisation ScienceDirect There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved The increasing demand for “finer cement” products, and the need for reduction in energy consumption and green house gas emissions, reinforces the need for grinding clinker grinding optimization

cement grinding achieved dolinabrukowapl

05/03/2021 Cement grinding optimisation ScienceDirect 01/11/2004 There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved The increasing demand for “finer cement” products, and the need for reduction in energy consumption and green house gas emissions, reinforces the need for Cement grinding optimisation ScienceDirect 01112004 The cement clinker grinding circuit reduces the feed from 80% passing size between 10 and 20 mm to 100% passing 90 μm The size reduction takes place in a two compartment tube mill; the first compartment of the mill is shorter than the second compartment Tube Cement Mill Optimisation In Cement Plant optimisation tube cement mill closed circuitScienceDirect 12th Global Conference on Sustainable Manufacturing Key Performance Indicators for Sustainable Manufacturing Evaluation in Cement Industry Elita Amrina *, ScienceDirect

holtec papers on cement mill optimisation

Cement grinding optimisation ScienceDirect This paper describes the tools , PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION , HOLTEC has undertaken Get A Quote Throughput Optimisation in Rolling Mills This BFI research focuses on improving throughput in the rolling mills To this end, equipment of the rolling mill was fitted with additional Cement Grinding Optimisation this paper describes the tools available for the analysis and optimisation of cement grinding circuits the application of the bond based methodology as ,predictive controller design for a cement ball mill grinding ,however, for optimising the cement plant, apart from of the cement grinding mill was studied by grognard et al, [25] using a statestudies for cement mill optimisation case study01/06/1971 The paper describes a computer control system for the optimisation of four cement kilns in Malmo, Sweden The scheme underwent acceptance trials in JuOnline Optimisation of Rotary Cement Kilns ScienceDirect

cement grinding optimization boulangerietretsfr

Cement grinding optimisation ScienceDirect Nov 01, 2004 The current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1% per annum The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding There is potential to optimise 01/02/2006 In air classifiers used in cement grinding circuits, an increase in separator feed tonnage causes an increase in the bypass (Benzer et al, 2001) Therefore, better classification would provide a margin for further decrease in specific energy consumption One solution of this problem is to use larger capacity classifiers However, air classifiers are expensive and occupy High pressure grinding rolls (HPGR ScienceDirect19/11/2016 Cement grinding optimisation ScienceDirect There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved The increasing demand for “finer cement” products, and the need for reduction in energy consumption and green house gas emissions, reinforces the need for grinding clinker grinding optimization

cement grinding conventional

Cement grinding optimisation ScienceDirect There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant progress has been achieved The increasing demand for “finer cement” products, and the need for reduction in energy consumption and green house gas emissions, reinforces the need for grinding Cement grinding optimisation ScienceDirect The current world consumption of cement is about 15 billion tonnes per annum and it is increasing at about 1% per annum The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding There is potential to optimise conventional cement report on cement grinding optimisation torque for stone This paper presents and discusses the results of a detailed study, which is based on industrial circuit testing on the subject of energy consumption in the comminution of cement clinker The study was performed in Turkish cement plants where highpressure roller press, tube mills and high efficiency separators are in operation Eight different grinding circuits configurations were Optimisation of Industrial Cement Grinding Circuits

cement grinding optimisation electricitehautemarnefr

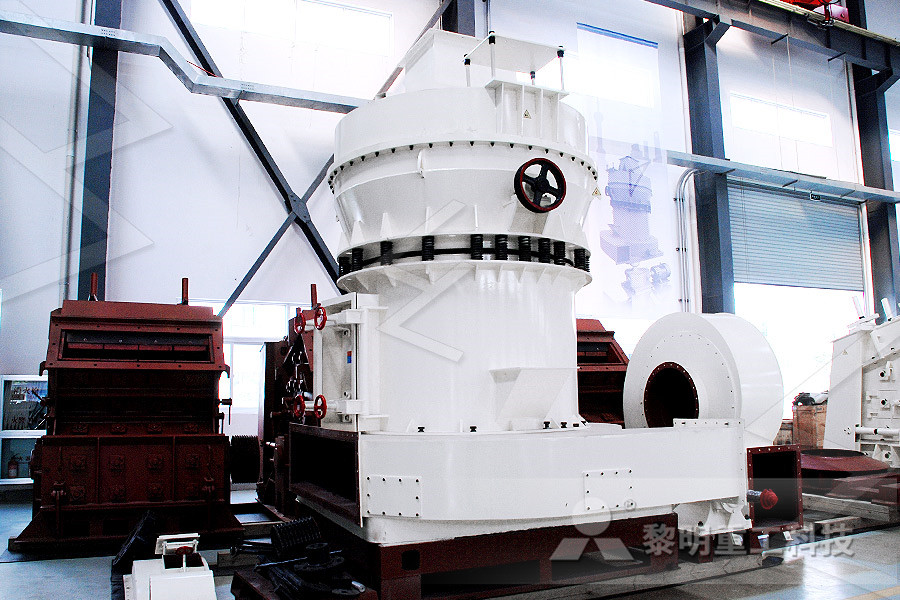

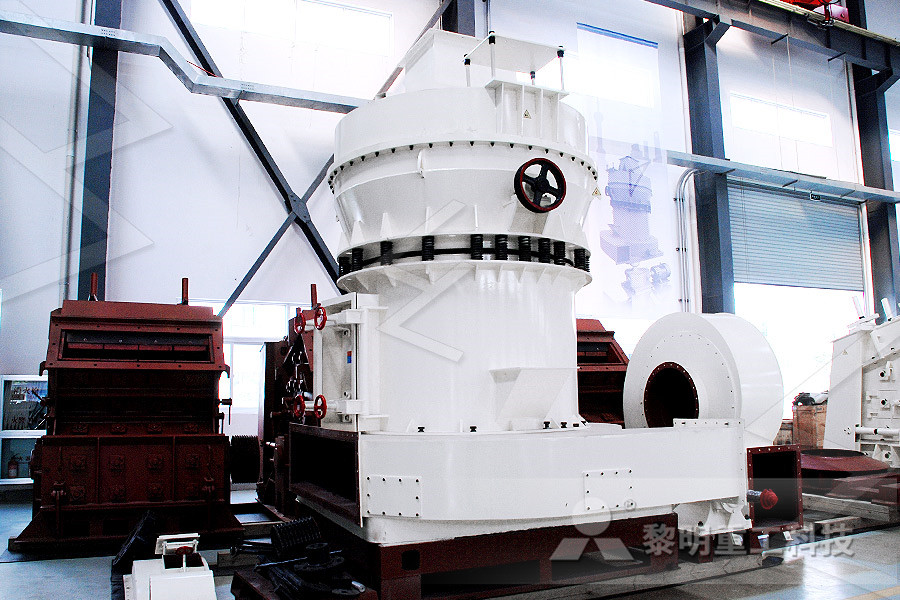

Cement grinding optimisationScienceDirect Nov 01 2004 The increasing demand for "finer cement" products and the need for reduction in energy consumption and green house gas emissions reinforces the need for grinding optimisation This paper describes the tools available for the analysis and optimisation of cement grinding circuits Chat OnlineVertical grinding mill Ultra fine vertical grinding mill MTW european grinding mill MB5X158 pendulum suspension grinding mill Trapezium millcement grinding optimisation aspinrollerCement Grinding Optimisation Sciencedirect Optimisationof The Ball Charge In Mills Forcement Grinding Cement Grinding Optimization Slideshare Jul 31 2014cement grinding optimization1cement grinding optimisationdr alex jankovic minerals process technology asiapacific brisbane australia alexjankovic com dr walter valery minerals Crusher Cement Grinding Optimisation Crusher For Sale